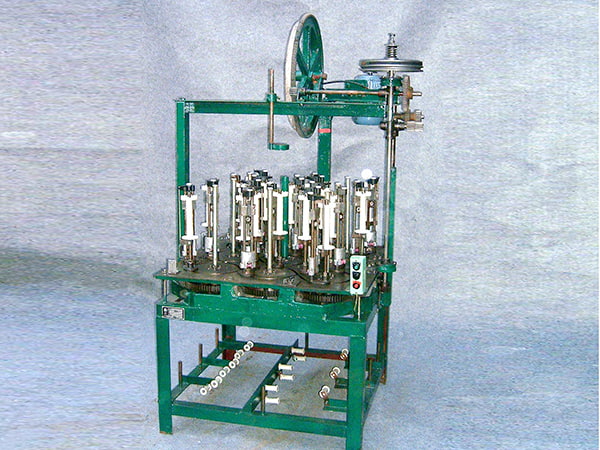

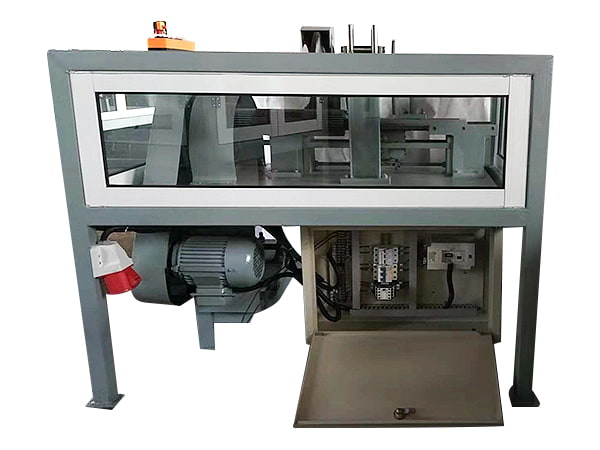

The SUNPASS Automatic Winding Machine enhances automated production capabilities, streamlining repetitive mechanical operations and ensuring consistent product quality in the manufacturing of wound gaskets. With the ability to simply add steel strips and filling materials, it can automatically produce wound gaskets with or without inner rings (standard type). The machine caters to a production diameter range from 15mm to 500mm, offering a versatile solution for various gasket production needs. Through the man-machine interface, the production quantity, number of circles, size and spot welding points, angle and welding power of the gasket can be preset. Under the control of the program microprocessor, the servo motor drives the inner ring or the gasket mold core, and at the same time makes the steel strip and the filler wind up, and automatically completes the spot welding. The automatic flat steel belt forming process not only saves the pre-pressing process, but also greatly improves the resilience of the gasket, reduces the pre-tightening force of the gasket, and improves the sealing performance of the gasket.