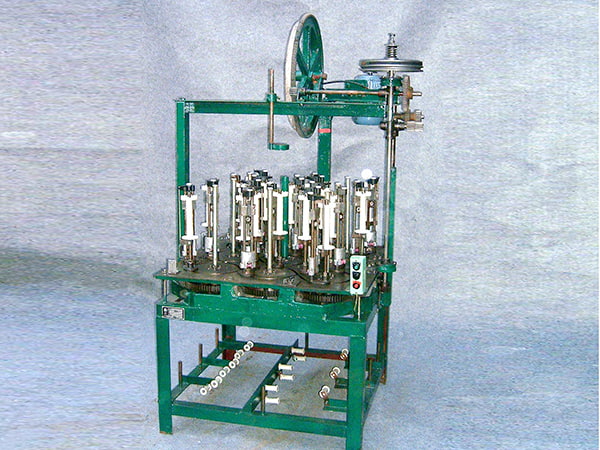

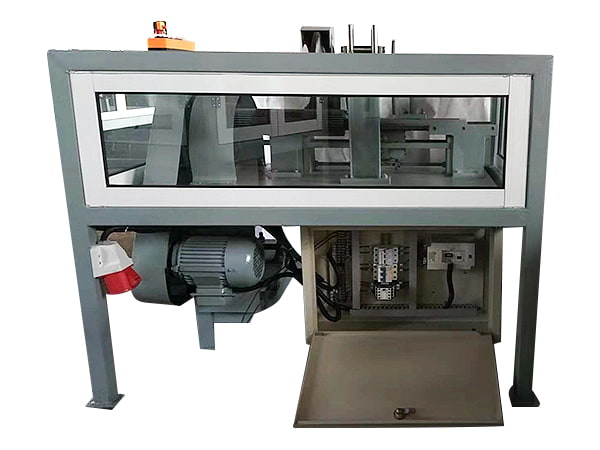

The SUNPASS CNC Milling and Ring Chamfering Dual-Purpose Machine is designed for precision milling of the outer ring on metal wound gaskets and chamfering the inner ring. It utilizes an air pump for pressure control and speed adjustment through frequency conversion technology. This machine eliminates the need for costly lathes, allowing one operator to manage multiple units efficiently, thereby conserving both labor and financial resources.

Notably, this versatile device is capable of milling grooves on halos with a diameter exceeding 150mm without being constrained by size specifications, making it an ideal choice for a wide range of applications.

Full application of industrial control PLC computer technology, automatic and precise control of the feed position, making the ring milling process simple and efficient. The unique design of the high rigidity of the milling guide rail and the machine head makes the machine multi-purpose, which can mill inner grooves, outer grooves, outer chamfers, and inner chamfers. Reduce customer duplication of investment.